美国国家航空航天局(NASA)和诺斯罗普·格鲁曼公司(Northrop Grumman)技术人员在犹他州海角(Promontory)为美国国家航空航天局(NASA)的深空火箭(deep space rocket)、太空发射系统(space Launch System)和猎户座(Orion)航天器的第二次飞行,对最后一个助推电机部分进行了绝缘处理。隔热层应用于每个钢电机段的内部,保护壳体免受发射和飞行过程中推进剂产生的热量。双五段固体火箭发动机助推器为SLS是有史以来最大的,最强大的固体推进剂助推器。SLS同时使用液体和固体推进剂来提供火箭发射和送入太空所需的推力。助推器在发射和前两分钟的飞行提供了超过75%的总推力。五个电机部分堆叠在一起,为每个助推器创建一个非常大的电机。今年早些时候,SLS和Orion首次试飞的全部10个发动机部件的制造和检验工作已经完成。

美国国家航空和宇宙航行局负责在2024年前将美国宇航员送上月球表面。SLS和猎户座是我们深空探索的支柱。SLS和猎户座将从美国宇航局位于佛罗里达州的肯尼迪航天中心发射,执行月球轨道门户的任务。美国宇航局计划2022年在猎户座飞船上测试SLS。

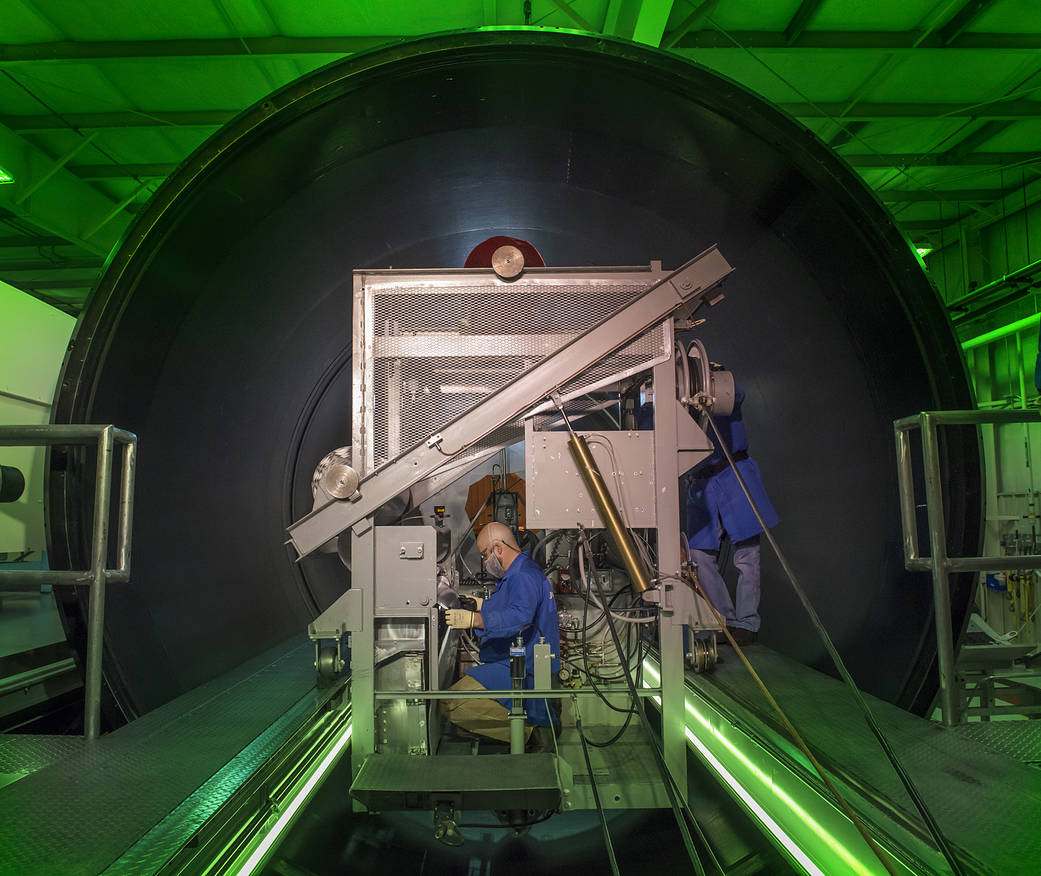

NASA and Northrop Grumman technicians in Promontory, Utah, have applied insulation to the final booster motor segment for the second flight of NASA’s deep space rocket, the Space Launch System, and NASA’s Orion spacecraft. The insulation, applied to the interior of each steel motor segment, protects the casing from the heat generated by the propellant during launch and flight. The twin, five-segment solid rocket motor boosters for SLS are the largest, most powerful solid propellant boosters ever built. SLS uses both liquid and solid propellant to provide the thrust needed to launch the vehicle and send it to space. The boosters provide more than 75% of the total thrust at launch and into the first two minutes of flight. Five motor segments are stacked together to create a single, very large motor for each booster. The manufacture and checkout of all 10 motor segments for the first test flight of SLS and Orion were completed earlier this year.

NASA is charged to get American astronauts to the surface of the Moon by 2024. SLS and the Orion are our backbone for deep space exploration. SLS and Orion will launch from NASA’s Kennedy Space Center in Florida on missions to the Gateway in lunar orbit. NASA is targeting 2022 to test SLS with astronauts aboard the Orion spacecraft.

Image Credit: Northrop Grumman Pho